‘The South Bowl: A Ceramic Bowl With A Carbon Offset’ by Jeremy Burnich, will launch on Kickstarter the first week of April 2017. Each South Bowl takes embodied CO2 into account and attempts to neutralize it's environmental impact with a voluntary carbon offset (VCO). The South Bowl's integrated carbon offsets will fund projects in renewable energy, forestry, and energy efficiency - over time reducing the emission of carbon and putting us on the road to a healthier planet.

The South Bowl offsets a 1/4 metric ton of carbon dioxide.

First Prototype of The South Bowl

“The South Bowl started about a year ago as I thought about the effects of climate change on Antarctica.” says designer Jeremy Burnich, “I started with a simple idea for a bowl shaped like the bottom of the world. I went through several design variations but got really motivated to go forward on this project when I got the idea to make it have a real effect on lowering carbon emissions. I felt like I had to do something in response to the short sighted environmental rollbacks the current occupant of the White House (I still can’t believe Trump won the 2016 election) is going forward with.”

The South Bowl is a small way to make a big difference.

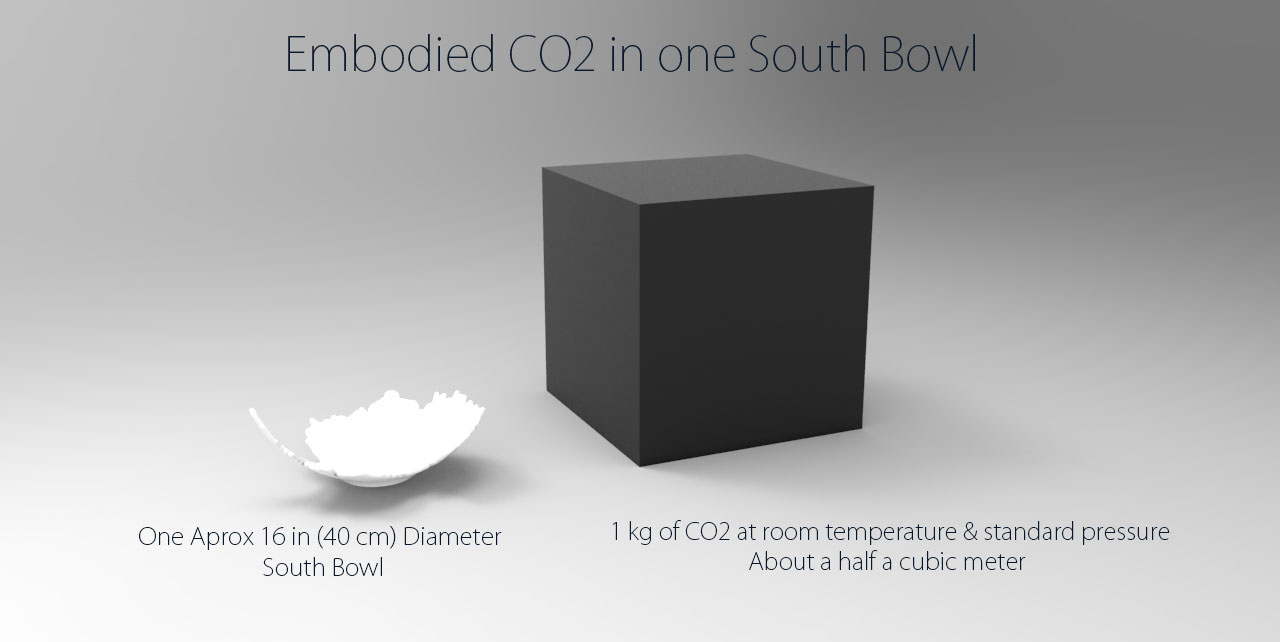

Every product you see has embodied energy - the energy that it took to create it and ship it to you. From bread to bricks to terrazzo tiles to toilets, every human made object has some sort of environmental impact. CO2 is part of every product you use. Most of our energy comes from burning fossil fuels, the burning of which releases carbon dioxide into the atmosphere, which in turn affects the climate.

For example, to be carbon neutral a South Bowl weighing an estimated 1 kg (it will probably weigh less) would have to offset approximately 0.7 to 1.0 kg of embodied carbon. This is a little more than half a cubic meter. That’s a box about 2 feet by 2 feet – around the size of a typical multifunction laser printer.

The South Bowl integrates a 250 kg carbon offset. If stacked in 1 kg cubes, the CO2 offset represented by one South Bowl would measure 8 feet deep and be 16 feet tall.

Will carbon offsets alone solve climate change? No, but taking environmental impact into account pushes us forward to better begin reducing the buildup of carbon pollution that is causing climate change. I believe in the concept of "aggregation of marginal gains.” If we improved every area related to carbon pollution by even just 1 percent, then those small gains would add up to remarkable improvement.

The Antarctic is the canary in the coal mine - the things happening there are harbingers of what's to come. Western Antarctica is warming faster than scientists thought possible. The fourth largest ice shelf on the continent appears likely to break off, creating one of the largest icebergs ever recorded. Scientists are growing increasingly concerned over the future of other ice shelves.

If you back The South Bowl, not only would you be helping create a well made and unique product (made in the United States by Mudshark Studios in Portland Oregon) you'd also be taking a positive step to combat climate change.

Production Partner

Mudshark Studios is a private label ceramic manufacturing company located in Portland Oregon. Mudshark Studios captured the attention of Martha Stewart, who honored them as rising stars in American arts and crafts.

Carbon Offsets

Carbonfund.org is leading the fight against global warming, making it easy and affordable for any individual, business or organization to reduce & offset their climate impact and hasten the transition to a clean energy future.

When launched on Kickstarter the South Bowl will sell for $68 (20% discount from it’s retail price). Early Bird Supporters get an even better deal of $54 (36% discount).

Other reward tiers will be available as well.

- SLS Nylon Prototype

- SLS Nylon Prototype

- SLS Nylon Prototype

- SLS Nylon Prototype

- SLS Nylon Prototype

The Production South Bowl:

- Diameter: The final diameter is set to be optimized and will be between 11 and 15 inches. (28 to 38 cm)

- Depth: Approximately 4.5 to 6 inches (11.5 - 15.2 cm)

- Material: Earthenware with gloss white glaze

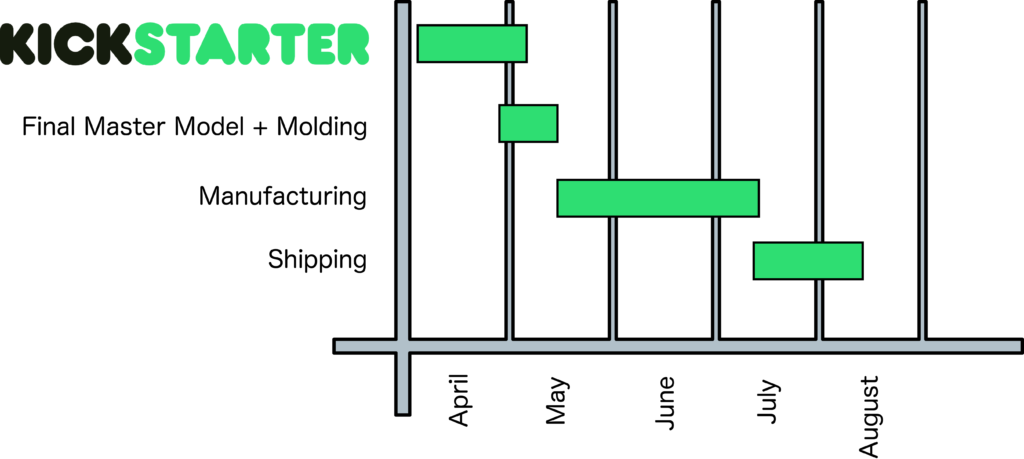

This campaign will run through April and into May. During that time one final 3D printed master will be produced and the molds modeled around it. The bowls will then be manufactured taking approximately 6 to 8 weeks. Fulfillment of orders follows in mid July.

![]()

No comments.