RAPID + TCT is North America's preeminent event for discovery, innovation, and networking in 3D manufacturing. For 2017 this event was held in Pittsburgh. I couldn't pass up the opportunity to attend.

I arrived Tuesday morning and was immediately blown away. I spent the next three hours walking around trying to take in and process everything on display. It was like a state fair but instead of Cutco knives, Shamwow's and wooden nicknacks there were titanium hip implants, custom motorcycle parts, and Materialise Magics. It was one amazing 3D printed process or machine or software tool after another.

There were numerous 3D printers on the floor - from large scale filament based printers cranking out vases in a scale of meters (rather than the millimeters I'm accustomed to working in) to big money industrial printers producing highly accurate and beautifully formed plastic and metal items in incredible detail and to incredibly high tolerances.

The metal prints are always the most amazing to me - because I know how expensive they are and how groundbreaking the technology is that makes those prints possible. That's not to say the plastic and resin prints are any less impressive.

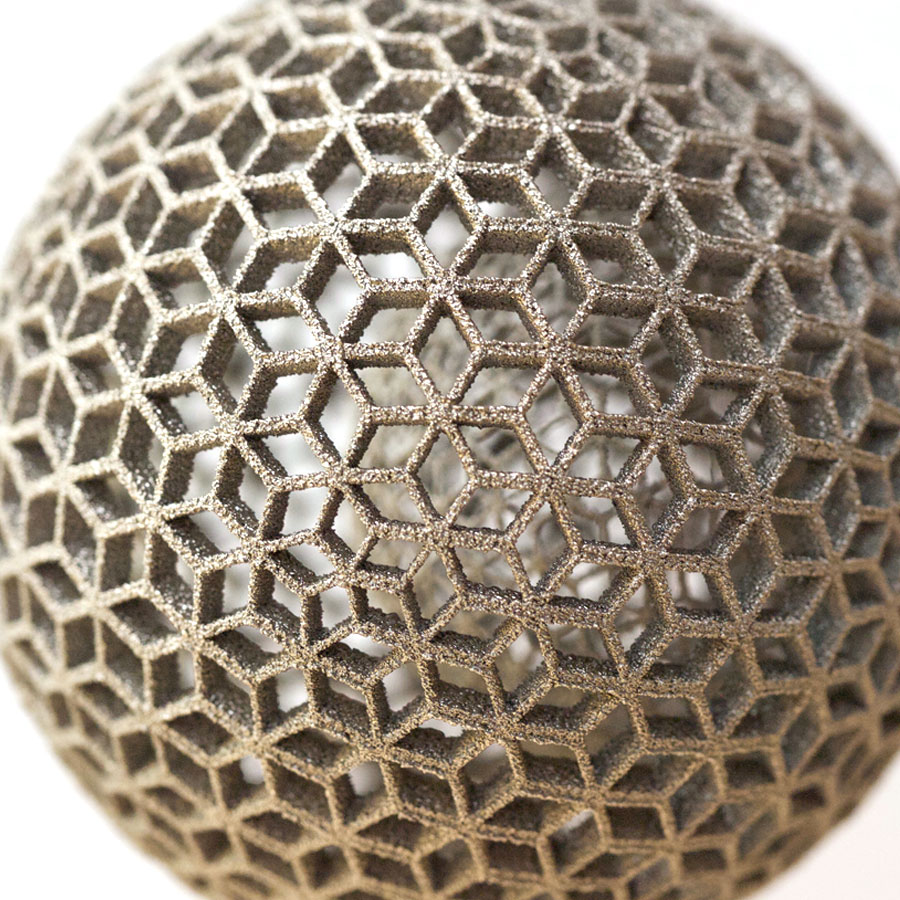

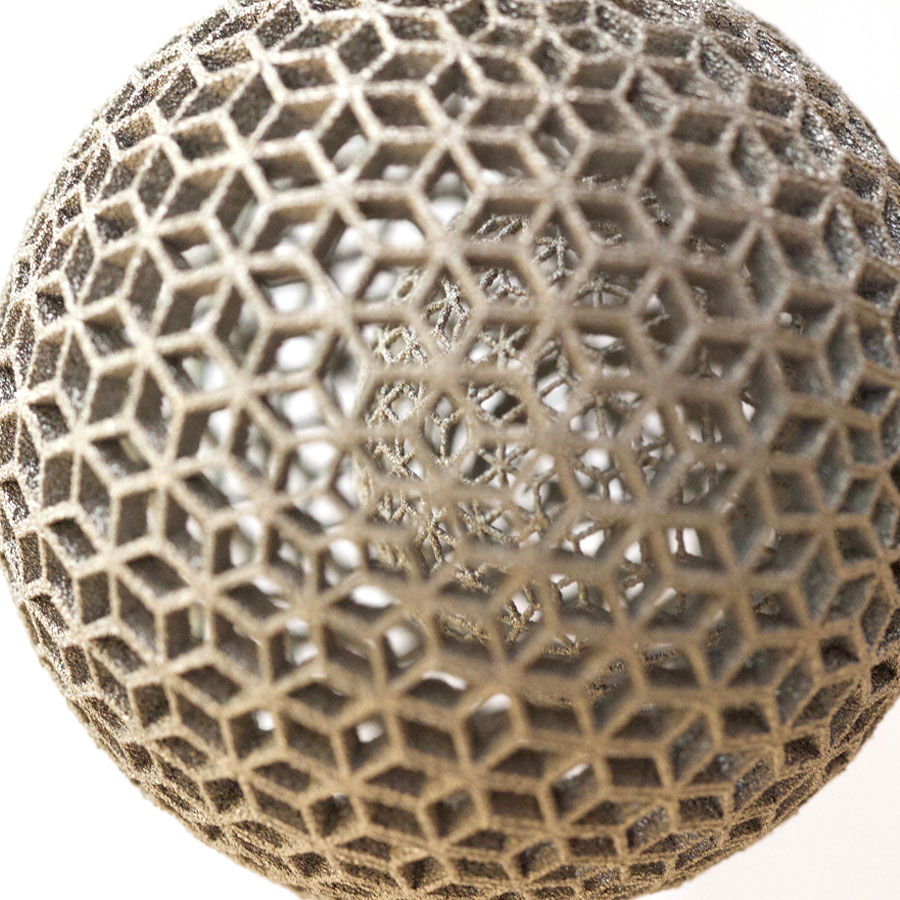

- A titanium sphere . . .

- inside a titanium sphere!

There's just something about a porous titanium ball with another porous titanium ball inside that is more wow inducing than the same thing done in nylon.

Some of the metal prints were fun, like a tiny metal whistle that Swedish company Höganäs printed in one go - with the metal pea printed at the same time the housing was made!

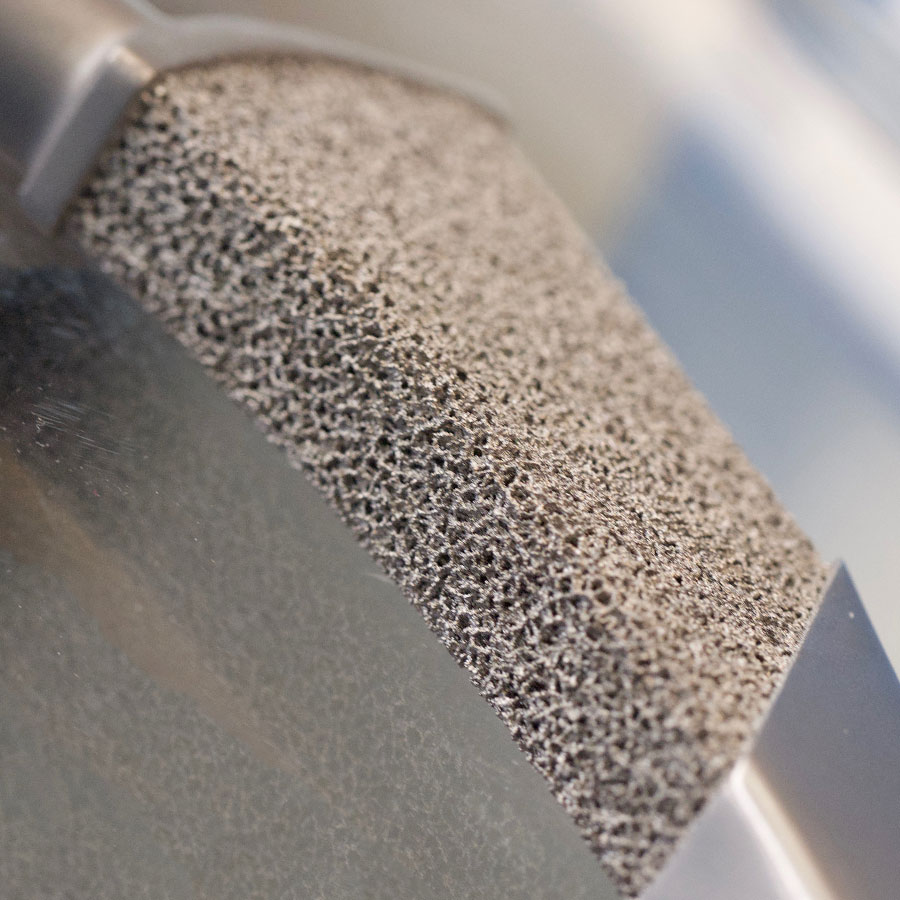

As you can imagine the potential of 3D printing in the medical field is enormous. Some of the most visually striking designs exhibited might never be seen by those who will be using them as they are meant for implantation into the human body. Not only are they technically demanding metal prints - micron accuracy and and seamlessly crafted to attach to a specific place on a bone - but they are also lovely objects to see.

But there were more than fancy metal prints I can assure you. In fact the HP multi jet fusion printer was being HEAVILY touted by pretty much every vendor on the floor. They all had some object that had been made using HP's technology. I was really impressed with the job Repliform did electroplating a fusion jet printed door handle. (Although I neglected to photograph the before and after) I did see the original handle at the HP booth. The electroplating improved the functionality of the handle - giving it strength and greater durability.

GE is also a major player in the additive manufacturing business. They had a lot of aviation related prints on display but what really caught my eye was this neat double headed wyrm that was fully articulated.

Of course the fully functional turbine engines were quite awesome too!

I'm fairly well informed about the 3D printing industry but attending this trade show made me feel truly like nothing more than an enthusiast - really far removed from the action of what's taking place in the industry. It's all about the money - the latest and greatest is EXPENSIVE and my budget is microscopic in comparison. But it was inspiring to see where the technology is now and catching a glimpse of where it's going.

I was so intrigued by the event that I went back the next day for a more focused and less wide-eyed walk through. I'm glad I went the second day because I engaged with more people and companies and learned a lot. I'm especially grateful to Chris Hickok, a software engineer at nTopology who took the time to go guide me through an issue I was having with a lattice design I was working on using their amazing Element software.

And last but not least, how could I not have taken a photo of a Death Trooper that 3DSystems printed from a galaxy far, far away.